House Planning Guide_Framing

- architect's desk

- Jul 29, 2023

- 2 min read

Framing

After the foundation has been constructed and allowed to cure for at least five days, framing generally begins. It is the phase in which the home’s structural skeleton is established and its rooms begin to o take shape. At no time in the construction process does progress seem faster. The farmers must be acquainted with every detail of the final plan, including insulation specifications, wall and floor finishing details, window and door sizes, mechanical installations, and plumbing fixture and cabinet placement, since they will be preparing the basis or the other trades to build on.

While you, as an owner builder, can’t be expected to know all the tricks of framing trade, you should have a general sense of the quality of materials used. Also check for straightness, squareness and accurate placement of frame elements based on the plan.

The most typical structural method used today is called platform framing. In this system, a floor frame is constructed on the foundation, then flooring underlayment is installed.

Wall frames, consisting of a sole plate, Studs ad top plates, are a set on top of the underlayment; then ceiling joints or the second-floor frame is constructed on top of the walls. The structural, or load bearing, frame is completed in sequence for each story from the ground up, and then the roof frame is built. After the structural frame is finished, carpenters will construct frames for non-loading bearing partitions that separate one room from the other.

The most typical structural method used today is called platform framing. In this system, a floor frame is constructed on the foundation, then flooring underlayment is installed.

Framing materials- long favored for their low cost, ease of use and widespread availability, construction-grade lumber is the most popular framing material. Depending on the region, any of a number of wood pieces may be used for framing, with Douglas fir and hemlock the most popular. Several new building systems offer alternatives to the

traditional wood frame. Whether used alone or integrated with conventional wood framing, engineered wood, lightweight steel and structural concrete often can compete equitably with solid wood, in both price and performance.

Quality stick framing- Because a stick frame consists of hundreds of individual pieces of wood, flaws in assembly may allow walls to shift or even fail under stress. The most common cause of failure includes an insufficient number of fasteners, excessive gaps, inferior lumber or a weak system of lateral bracing. To avoid future problems, be sure to watch for the following pitfalls.

Depending on the region, any of a

number of wood pieces, any of a number of wood pieces

may be used for framing.

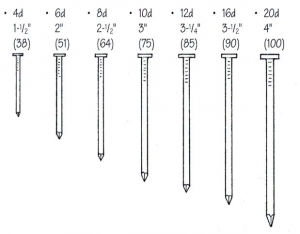

Improper nailing- Building codes recommend a specific number of nails based on lumber dimensions. To attach a vertical 2x4 stud to a sole plate, for example, a good builder typically uses four nail two for each face to keep the stud from twisting. Using too many nails can result in splitting. Ask your builder to explain the nailing schedule that will be used when framing your home.

Comentários